2013-12-09 In the beginning … there was an MGB (What else do you need to know?)

<<To make the type look larger, hit the <Ctrl> key and the <+> (plus sign) key at the same time – maybe several times to make the type much larger. To make the type look smaller, hit the <Ctrl> key and the <-> (minus sign) key. WordPress, the host of the website has fixed type -or- I’m still learning about all of the features. At any rate, with my aging eyes, I find it best to make the type larger when reading stories.>> <<Second note: Dad calls me ‘Puddin’. I wanted a unique name for the website, so I decided to use the name that Dad calls me.>>

————————————————————————————————-

Oprah said “Every person has a story”. I believe that every CAR has a story. (Or, at least the OWNER does. This is the story of me getting an MGB – a British “Touring Car”.

————————————————————————————————-

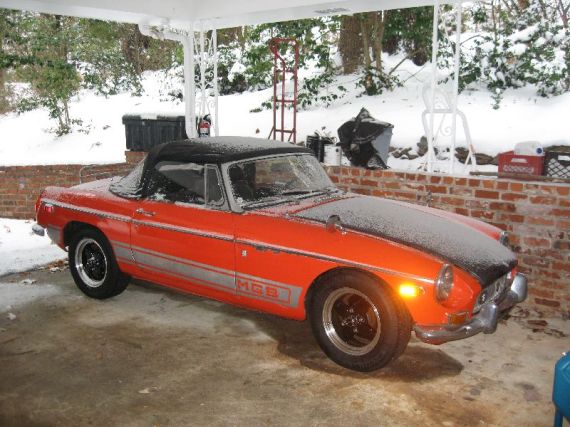

My MG was given to me by my older brother, Kenny. It is a 1971 MGB – and it’s ‘not pretty’ to anyone but ME! Kenny had worked with Dad at a small SC Ford Dealership and Dad retired. Kenny took the MGB as a trade-in and kept it. He had it 15 years and had enjoyed driving it in the Savannah/Statesboro area. The MG was ‘drive-able’, but sat for a while when Kenny turned his attention to house repairs, RV’s, boats, limousine, -and- just life. Over the years, I had asked him several times about it. About early 2000, he said it was parked and he hadn’t driven it in a while. A few years later, I asked him how much he wanted for it. He gave me a figure and I asked “Is that the ‘family price’?”. A few more years passed and Kenny had seen a Willy’s Jeep restored and he decided that he really wanted restore a 41 Jeep that he had. That meant that he was really no longer interested in the MG. He considered it a ‘special car’ and I can also guess that he really didn’t want to sell it. About 5 years ago, I asked him about the MG again – and this time he said that he would GIVE it to me – because he wanted to restore the Jeep. So, he came to visit me in Atlanta and he drove the RV with the MG in tow. We went to the highway department and put it in my name. (I don’t remember the date that all of this happened because I am writing it at a later date.) <The highway department clerk asked how much I paid for it. I didn’t really want to reply “nothing” so I said “$1”. Kenny was standing at the office window with me and about the same time he said “nothing”. So the clerk took the title that he had and put it in my name – and that was IT. I also owned a 1976 Chevy Nova and years before, drove it to the highway department with a bill-of-sale to apply for a title. A highway department employee went outside with me to ‘inspect’ it. I had assumed that an inspection of the MG would also occur, but it didn’t.) <Note: In the state of Georgia, for an older car, no title is necessary. The owner only needs a yearly registration in their name and pay taxes on the vehicle. The newer cars (not trucks and vans) need to have an emission inspection. Taxes on the MG are $20/yr. Antique insurance is $100/yr.)

At first, the MG remained parked in my carport because I was concerned about driving it in Atlanta traffic. I was able to find Jeff, who agreed to install new floor pans – so that the seats could be bolted in. When I tried to drive it to Jeff’s garage, it broke down and I had to be towed. So much for the first time trying to drive it. A few months later, Kenny came to visit, Jeff had completed the work and I was able to get Kenny to drive it home for me. (Note: Jeff also replaced the rocker panels by welding in new ones from a parts supplier.) Kenny gave me driving lessons and encouraged me to ‘take it around the block’ and I did. However, I still didn’t feel comfortable driving it. Also, Kenny installed the new convertible top that I had ordered. I was really pleased to come home from work one day to find out that he had worked on it for me. He also bolted the seats into the new floor pans. (He didn’t tell me the other parts that he worked on, he was still teaching me to drive it.)

The floor pans are just above the mufflers and driving the car was noticably loud. I asked the ‘gearheads’ at Dandy Donuts for a recommendation of a muffler repair shop. I was given the name of a shop on Buford Highway and one of my sons drove me there. We talked with the technicians and they said it would be “a job – especially if the bolts into the header broke off”. We made an appointment and my son drove the car to the shop for me. I followed in the family car and we returned home to await for the repair to be complete. As you would guess, the repair shop reported that a major bolt did break off. However, the shop was able to get the bolt out with much effort and a few weeks later, I was able to get my son to drive it home for me. (We had to drive after work and Atlanta traffic is a major ‘rush-hour’ bottleneck.)

A few months later, I talked with an auto electrical shop who agreed to put in a front wiring harness for me. I supplied a wiring harness from one of the MG parts suppliers. When Kenny had let it sit for a while in Savannah, someone tried to steal it and broke the plastic cowl around the steering column. With the intention of ‘hot-wiring’ the car as is seen in many movies, they cut many of the wires to the ignition switch and to other parts. Kenny had pieced them back together – but, I wasn’t very secure with all the patches. So, on Kenny’s next visit, I asked him to drive the MG to the shop for me. It was there for about nine months waiting for the technician to ‘get to it’. (I was warned when I took it there, that the new harness would be a ‘back-burner’ project and may take a while. I checked on it every couple of weeks after work and talked with the manager and repairman. John actually did the work and he said that it was ‘quite a job’. He had done several other MGs and knew was ‘experienced’. He even replaced the dash bulbs when he had it apart because he knew how difficult it was to ge to that area after assembly.) Finally, the day came that the wiring was finished. I drove to the auto shop before closing and paid for the installation of the wires. Then, I drove the MG home one night after work. (It was cold and rainy and I was proud of myself for getting home.) I walked to the nearest MARTA station, caught the train and bus back to the closed shop and drove my ‘family’ car home. Mission accomplished – new wiring in the MG. (And I made it home.)

My younger son moved back home after college and said that he would work on the car for me. He ordered a ‘bunch of parts’ and I bought many tools and whatever was needed. I told Kenny that Ray was going to work on the car for me. I told him that Ray had ordered a carburetor rebuild kit and many parts – leaf springs, hood, bunches of stuff. Kenny replied “Don’t take apart the carburetor – they are matched and hard to get synched”. That afternoon wen I got home from work, Ray announced that he had started the work with a carburator rebuild and finished it. I thought “uh oh”. I asked him if it ran OK and he replied ‘yes’ – So-o-o I didn’t have anything else to say.

Ray worked on it through the winter – oil change, new spark plugs, new wires, new shocks, new brakes, and bushings. He had a lot of difficulty with many rusted bolts. He went back to college and to this day, I still have a valence that needs to be installed. (I even found the bolts for installation in a plastic bag and keep them on the console.)

Through the months, I seemed to be plagued with flat tires. I would take it off, go to a nearby tire store and buy a new one and put it on. I bought tires one at a time. Eventually, I had new tires on the whole car. I continued having a flat tire due to a slow leak. The tire shop and I were well-aquainted with one another and one day, one of the employees finally confessed that I had a rim that is rusty inside. The tire shop has been very gracious about taking the tire off the rim, putting new bead on the rim and trying again to keep a slow leak from re-occurring. However, I just got tired of constantly dealing with flat tires. The internet shopping scene had evolved and I had learned google search too well. I found an aluminum rim on the internet and ordered 4. They arrived and I took them to the tire store and requested a dependable name-brand tire. The tire store ordered them and did the mounting and balancing. I already had spacers on the back and the tire store had some spacers in the shop that had to be customized for the front. They front spaces needed a little more metal off the inside in order to fit comfortably, so the shop manager found a file and spent his time making sure that the rim installation and fit was proper.

After getting the car, I learned of a special English parts store in Decatur named Atlanta Imported Auto Parts. I visited there many times and bought various parts. One day, while browsing in the store, I picked up a newsletter from the Peachtree MG Club. I didn’t know that Atlanta HAD a MG club until I saw that newsletter. So, I found out when the club meetings were and attended. My first meeting was after June, so they said that I could join at half-price since most of the year was past. The club membership year starts in January. I joined and started receiving a mailed newsletter each month. That was several years ago and now the club has a ‘members-only’ emailed newsletter.

The Atlanta MG club had a spring ‘tune-up’ Tech session and Tom and Kathy’s house in 2007. Kenny was visiting and agreed to drive us to the club meeting. We got terribly lost on the way there and were embarrassed at not being able to follow the directions. (Our map had turn-here turn-there direction without any distance between the turns. We didn’t know the area well and got lost in a residental subdivision in the suburbs. The club sent someone to a major cross-road intersection for us to follow to the house. Not a good start for a new member.) At the tech session, Barry (the Tech Director) asked Kenny to crank the car so he could diagnose if it needed spark plugs, compression check etc. When Kenny cranked it, there was a popping noise from the carburetor. Barry immediately said that it needed new throttle shafts – the ones that it had were worn and the pop came from the carburetor. Kenny and I made it home without incident, but I kept in my mind – “the MG needs throttle shafts”. (Note: I also learned that day what ‘throttle shafts’ are.)

<Throttle Shafts> A few months later, Rhonda and Jim agreed to sponsor a tech session at their house and garage. (It was winter and they have a very nice, HEATED garage with a car lift.) I said that I needed new throttle shafts – Jim said that he would show us how to install new ones, we set a date for the Tech Session and my MG and ‘throttle shafts’ were on the agenda. I ordered the parts. (Thankfully, there are not many different ones that could be ordered and I received the right ones.) The morning of the tech session, I had only driven the car successfully a couple of times — but, I was determined to try and get it there. (It was cold and I had to really bundle up to drive the MG – if the heater works, I still don’t know how to turn it on. To get to Rhonda and Jim’s house, I had to drive about 30 miles.) Jim had agreed to tow me if I didn’t make it. I had my cell phone handy and tried to leave early so that I could drive back roads. (I concerned about having to drive a higher speed on the interstate as the odometer/speedometer doesn’t work.) Well, I got lost immediately on the back roads, found an interstate and changed my mind about the interstate route because – by that time, I was running late and I knew that the road was a straight one without many turns. I knew that my gas showed low and with the distance to drive, I had to stop for gas, I filled the tank up and near the end of the fill-up, about a pint of gas overflowed onto the pavement. I was holding the gas pump handle and I didn’t let gas overflow at the tank port. When Kenny and I had filled the tank up previously, Kenny had the pump handle and there was a strong gas smell, but I don’t remember seeing gas under the car. I didn’t want to crank the car with a gas puddle underneath it , so – I pushed the car away from the gas, got in and continued on to the tech session.

I made it to the Acworth exit, took a left to go across the bridge on the interstate and the car quit running just after I got over the bridge. I rolled to the side of the road and tried several times to crank it. It wouldn’t respond to anything that I tried. I called Rhonda and she told Jim where I had broken down. A few minutes later, Jim and Larry came to my rescue and TOWED ME TO THE TECH SESSION! Thankfully, I was only a couple of miles away and the problem was, easy for a knowledgable group – the points were worn out.

At the tech session, Jim put the new throttle shafts in for me. This involved completely disassembling the carburetor and replacing the ‘pencil like’ part that has a butterfly valve opening/closing for the air intake. A real learning experience for me and several others who attended. Also, Larry and Jim colaborated to hook-up my loose emergency brake cable – AND – they installed a drivers seat belt for me. (Thanks to TomG from the MG Club for the seat belts.) I drove the car, and Rhonda was a brave passenger when they told me to ‘drive it around the block’ to make sure that it was OK. We returned with a ‘thumbs-up’ and we began to wrap-up the tech session.

<Tire Spacers> I asked Jim and the group about the rubbing noise in the back and Jim noticed that I had regular rims and that a spacer was needed in the back to keep the tires from rubbing against the wheel well. (I learned that the wire-rims designed for the wheel-well were a different size than the steel rims that my brother had on it.) Jim had an extra set, put them on for me and then asked what I needed next. I was estatic about all of the work that had been done and really hadn’t written down a list. It had been several hours of repair and we were all ready to call it the ‘end of this session’.

By the end of the day, Jim and the club had really helped tremendously.What a day! I was excited to drive the car home. (And I felt more confident on the return drive home on the interstate. Larry let me follow him so that if something happened on the way home, I would have some help. Thanks, Larry.)

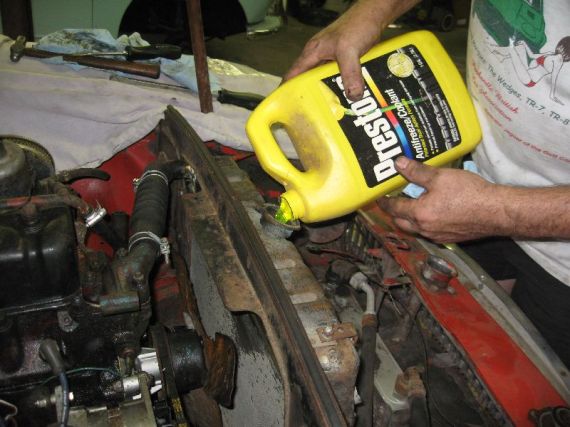

<Rubber Parts/GasTank> After that, I drove the MG several times to Dandy Donuts on Saturday mornings. Also, I would drive it in the neighborhood to run errands. One spring morning, several years ago, when I put the top down. I really enjoyed the feeling of the warm air and the drive. I was continuing to get more comfortable with changing gears and going uphill for the left turn into the street to my house. I continued to attend Peachtree MG club meetings and as many Tech Sessions as I could. I talked with Barry about working on it to ‘tune it up’. He and I agreed on a date and I drove it to his garage early one morning before work. It was a freeze in Atlanta that morning and I wore a lot of clothes and a couple pair of socks inside hiking boots. I made it there, and he gave me a ride to the ‘Big Chicken’ in Marietta to catch the bus home. I missed the Dunwoody bus by 10 minutes. I ended up going to the transfer station in Cobb and riding to the rapid-transit-train station at the Arts Center. I then rode back to Perimeter Mall and walked home. After changing clothes, I went to work – getting there ‘very late’. At that time, I didn’t really have a list of items to fix, I asked Barry to replace anything that he thought would be a safety issue. He installed a new gas tank – the old gas tank had holes on top where debris gathers under a part of the back and rusts the top. (Yes, I would say that having gas overflow the tank at the gas station and leave a puddle of gas under the car is a ‘safety issue’.) The radiator hose was very old, the radiator had a small crack at the top that needed welding, the engine and transmission mounts needed replacing, and Barry was able to get a motor for the windshield wipers repaired. In addition, he put in a new master brake cylinder and too many smaller items to be listed. I think that he also worked on the clutch. After several weeks of work, he brought it home for me after an MG meeting. I was overjoyed – the ‘car project’ had taken a giant step in becoming safe and reliable.

Note: When Barry drove the MG to my house after the monthly meeting, it was dark and the passenger headlight wasn’t burning when he arrived at my house. I have to include in this post that I installed the new headlight. I am not very mechanically proficient, but I am willing to learn -and- willing to try and repair ‘simple’ things that I think that I can accomplish.

<Starter> A few week-ends after the Barry ‘rubber replacement’ repairs, I drove it to Dandy Donuts for the Saturday morning ‘gearheads’ meeting – i.e., eat donuts and talk about cars. Afterward, I went to a local auto parts store for a red battery cable. The car wouldn’t start in the auto store parking lot- UG! A store employee brought out a portable battery to make sure that the battery was OK. Next, a mechanic who was in the store as a customer offered to help. He looked over the engine of the car, messed with some items under the hood and asked me to crank it several times – no luck, just a click and no turnover. He then said that he thought that it was the starter. He asked a the store employee to help him push the car a short distance up a hill in the parking lot. I got in and after it started rolling, I had the key turned to the ‘on’ position and let the clutch out – as instructed. IT CRANKED when it was rolling. I let it idle, talked with the mechanic, got his work phone number and told him that I would order a starter and bring it to him for repair. I drove it home and backed it into the driveway – because the driveway faces downhill. I returned in my ‘other’ car to the auto store and ordered a starter. The next day, I was talking with Kenny and told him about ordering a starter. He said that the problem was most likely the starter relay. (I didn’t know what one was and had never heard of one.) I returned to the auto store and ordered a starter relay. I called the ‘parking lot mechanic’ and made an appointment for the installation. I was concerned about driving it to Barry because of the distance. His shop is about 25 miles from my house and if the car quit running on the way, I envisioned a large tow bill. I preferred to try and drive a short distance to a local mechanic. Well – was I ever WRONG!! The shop gave me a ride home and several days later, they called and said that they had a problem with the starter. Since it was a ‘user supplied part’, I picked it up, returned it to the parts store with the receipt. The store that I had purchased it from didn’t have another one of that type in stock. I had to drive to a nearby store, ten miles away to get the type that I required. When I got to the ‘other’ store, they told me there was a computer error, the required starter really wasn’t in-stock. I returned to the nearby store and they put in an order for the part. It was about 8pm and they said that it would arrive by 7:30 the next morning. My thought was ‘sure – I believe that’. But, what was I to do? I left and told them that I would return at 7:30 in the morning. Well, much to my surprise, the part was available the next morning at 7:30 and I picked it up and took it to the repair shop. The repair shop installed it and said that I could pick up the MG that afternoon. (By the way, the auto store had a bench to test starters and told me that the first starter passed their test and had nothing wrong. UG!!!) Anyway, I drove the car home. Within a few days, I drove the car several times and noticed that the turn signals were not working. I called the repair shop and they claimed that they had not done anything with the signals.

<Turn Signal> Several months later, I asked Barry to repair some items on the car and the turn signal repair was ‘on the list’. Well, at Barry’s shop, he found where my new wiring harness had a green wire cut under the dashboard. He traced the wires and was able to test for the turn signal and determined that the cut green wire was the culprit. He had a difficult time repairing the wire as the cut was near the terminal and there was barely enough length of wire near the terminal for him to properly attach it. I had learned an important MG repair lesson – i.e., maybe it is better to drive a crippled car to Barry and take a chance of having to call a tow service than to let a ‘yahoo’ mechanic work on it. I’m convinced that the mechanic didn’t know about British cars and was learning by working on my car and making mistakes, which included stripping wires to determine which one was the one that had current flow to the starter. Barry aligned the tires at my request since the tire store did not perform alignments.

As I write this post on the blog, I admit that I have made mistakes with my MG but – I have learned to drive it and depend on it for errands in my neighborhood. I have more ‘repair’ stories to tell and will wait for another time to write them. The adventure has begun – a 1971 MGB is LOOSE in Atlanta!

<<Wordpress, the blog host, puts advertising on blogs. It is the price that a blogger has to pay for the hosting ‘free’ service. I cannot control the advertising. On another note, please feel free to tell me your comments and/or suggestions. I would appreciate any information about the blog that you wish to share with me. If you prefer to not have the world view your comment (as what would occur if you post to this page, you may either tell me about it the next time we meet or send me an email. Thank you.>>